TAYU Machinery Co.,Ltd.

- Address:Xianlin Industrial Zone,

Yuhang, Hangzhou, China - TEL:0086-571-88687337

- FAX:0086-571-88686887

- Email:hztayu@aliyun.com

- QQ:

- alibaba trademanager:

- injection-molding-machine.tayu.cn

Your current location:home > Product > Rubber MachineRubber Machine

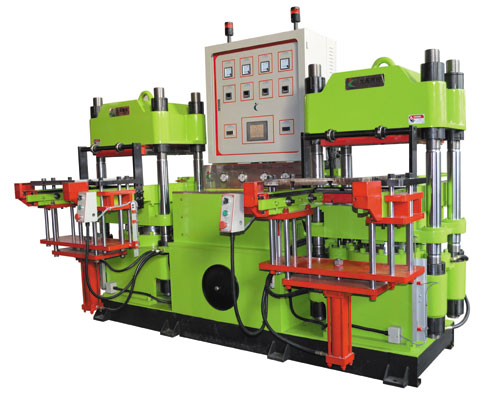

Vulcanizing machine

Tayu Machinery is professional development of rubber machine manufacturers, the introduction of the European advanced technology, the quality of choice, the main products: rubber machine, angle rubber machine, vulcanizing machine, vulcanizing machine and other major series, dozens of products sold nationwide and around the world 100% to meet customer demand, service-oriented

Vulcanizing machine features introduced:

1, dual-motor dual-pump dual hydraulic system design, two working positions independently controlled, independent operation, when two operating positions curing time and take the time to stagger products, only one operation, the equivalent of one person to operate two machines;

2, the former top Clamping way out of the mold clamping mechanism, the mold is opened in front of the machine, easy to take products;

3, using high vacuum vacuum hood design, can mold is nearly complete vacuum environment, improve the mold exhaust performance;

4, countertops installation mold venting strong spring, with vacuum system, no bubbles forming high-quality products;

5, vacuum hood within 4 seconds to complete the vacuum of -650mmHG the above, for molding easy, requiring precision of the finished product is most suitable;

6, the machine fully functional, fit to be repeated mold and structural diversity of the mold, the next shot and thimble optional equipment;

7, the clamping force per unit area is large, ensure seamless mold together tightly, no flash products, good quality.

Application:

O-ring, packing, keyboard, drum, shoes, medical drugs plugs, shock products, gaskets, conductive supplies, electronics and other supplies precision edge applications.

Vulcanizing machine features introduced:

1, dual-motor dual-pump dual hydraulic system design, two working positions independently controlled, independent operation, when two operating positions curing time and take the time to stagger products, only one operation, the equivalent of one person to operate two machines;

2, the former top Clamping way out of the mold clamping mechanism, the mold is opened in front of the machine, easy to take products;

3, using high vacuum vacuum hood design, can mold is nearly complete vacuum environment, improve the mold exhaust performance;

4, countertops installation mold venting strong spring, with vacuum system, no bubbles forming high-quality products;

5, vacuum hood within 4 seconds to complete the vacuum of -650mmHG the above, for molding easy, requiring precision of the finished product is most suitable;

6, the machine fully functional, fit to be repeated mold and structural diversity of the mold, the next shot and thimble optional equipment;

7, the clamping force per unit area is large, ensure seamless mold together tightly, no flash products, good quality.

Application:

O-ring, packing, keyboard, drum, shoes, medical drugs plugs, shock products, gaskets, conductive supplies, electronics and other supplies precision edge applications.

Technical parameters

| 机型 Type | TFS-200 | TFS-250 | TFS-300 |

| 锁模力 Clamping force(Ton) | 200 | 250 | 300 |

| 行程Stroke(mm) | 250 | 250 | 250 |

| 台面Heabngplate size(mm) | 540*560 | 600*650 | 650*650 |

| 缸径Dimeter of cyhnder(mm) | 350 | 400 | 450 |

| 马力Horse power(HP) | 10×2 | 10×2 | 10×2 |

| 总功率Total power(KW) | 40 | 53 | 53 |

| 重量Gross weight(TON) | 6.5 | 8.5 | 11 |

| 机台尺寸Machine size(m) | 3×2.05×2.3 | 3.3×2.1×2.3 | 3.35×2.55×2.4 |

Template size

Related Products

Recommend: Injection Molding Machine Vertical Injection Molding Machine Bakelite Injection Molding Machine BMC injection molding machine Insert injection molding machine