- New Product

- TY Series Injection Molding Machine

- TC Series Injection Molding Machine

- TK Series Injection Molding Machine

- Rubber injection molding machine

- Special Machine Series

- LSR liquid silicone injection molding machines

- Multi color rotary table Series

- Bakelite special Machine Series

- Examples of samples

TAYU Machinery Co.,Ltd.

- Address:Xianlin Industrial Zone,

Yuhang, Hangzhou, China - TEL:0086-571-88687337

- FAX:0086-571-88686887

- Email:sales@tayu.cn

- QQ:

- alibaba trademanager:

- injection-molding-machine.tayu.cn

Your current location:home > Product > Multi color rotary table SeriesMulti color rotary table Series

TK-3500.2C Large Two-color injection molding machine

TAYU Machinery Co.,Ltd is one of the most professional vertical injection molding machine manufacturer in China. It possesses two core manufacture bases in Zhejiang Hangzhou and Guangdong Dongguan respectively.The main production:Vertical injection molding machine,Rotary injection molding machine,Two-color injection molding machine,Bakelite Injection Molding Machine,Servo Injection Molding Machine,Golf injection molding machine,Liquid silicone injection molding machine,Skateboard injection molding machine,Zipper machine,Silicone Machine,Double Slide Vertical injection molding machine,Toothbrush Injection Molding Machine

TK-3500.2C Characteristics of vertical injection molding machine:

﹡With the development of plastic products, plastic machinery has trend the characteristic towards “individuation, specificity”. Rely on international advance technology, TAYU developed new generation product---TK-3500.2C large scale vertical bi-color injection molding machine, the humanization design idea, show energy saving, environmental protection and high efficiency totally. It developed by the special use of client, clamping force 350ton, shot weight 7000gram, it’s the largest scale vertical bi-color injection molding machine since the beginning of vertical injection molding machine history.

﹡Two sets of feed pipes fit one of compound nozzle, double-colored, machine is adopted and moulds is matched, so that the processing and manufacturing process are reduced greatly which saves 2/3 of the original production time. Besides, the double-colored one-off molding reduces the quality problems caused by cooling shrinkage. For the customers, it not only reduces production costs largely, but also improves the quality of products and creates more profit.

TK-3500.2C Characteristics of vertical injection molding machine:

﹡With the development of plastic products, plastic machinery has trend the characteristic towards “individuation, specificity”. Rely on international advance technology, TAYU developed new generation product---TK-3500.2C large scale vertical bi-color injection molding machine, the humanization design idea, show energy saving, environmental protection and high efficiency totally. It developed by the special use of client, clamping force 350ton, shot weight 7000gram, it’s the largest scale vertical bi-color injection molding machine since the beginning of vertical injection molding machine history.

﹡Two sets of feed pipes fit one of compound nozzle, double-colored, machine is adopted and moulds is matched, so that the processing and manufacturing process are reduced greatly which saves 2/3 of the original production time. Besides, the double-colored one-off molding reduces the quality problems caused by cooling shrinkage. For the customers, it not only reduces production costs largely, but also improves the quality of products and creates more profit.

Technical parameters

| 型号 | Model | Units | TK3500-2C | ||

|

射

出

系

统 |

螺杆直径 | Screw Diameter | mm | Ф95 | Ф95 |

| 射出压力 | Injection Pressure | Kg/cm2 | 1216 | 1216 | |

| 理论射出容 | Theoretical Shot volume | cm3 | 3896.5 | 3896.5 | |

| 射出量(P.S) | Max. Shot Weight | g/Oz | 3682/129.6 | 3682/129.6 | |

| 射出率 | Injection Rate | cm3/sec | 557 | 557 | |

| 温控区 | Temperature Control | ZONE | 18 | ||

| 料斗容量 | Material Hopper Capacity | L | 60 | ||

|

锁

模

系

统 |

合模力 | Clamping Force | T | 350 | |

| 开模力 | Opening Force | T | 15 | ||

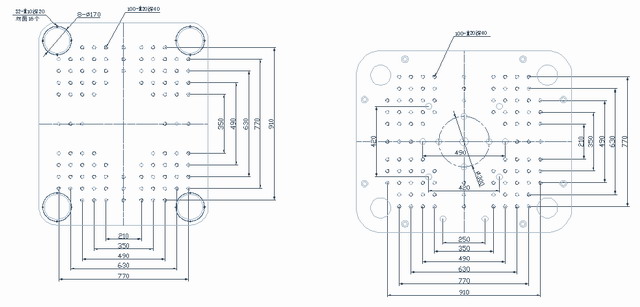

| 模柱间距 | istance Between Tie Bare | mm | 860x660 | ||

| 最小模厚 | Min Mold Height | mm | 750 | ||

| 开模行程 | Opening Stroke | mm | 450 | ||

| 最大开模距 | Max. Open Daylight | mm | 1200 | ||

| 射嘴中心 | Nozzle Center Height | mm | 415±20 | ||

| 两个射嘴中心距 | Nozzle Center Distance | mm | 450-1150 | ||

| 顶出力量 | Ejector Force | T | 6.1 | ||

| 顶出行程 | Ejector stoke | mm | 150 | ||

|

液

电

力

系

统 |

最大液压 | Max. Hydraulic Pressure | Kg/cm2 | 140 | |

| 作动油量 | Pump Output | L | 420 | ||

| 油泵电机 | Pump Motor Power | Kw | 74 | ||

| 电热容量 | Barrel Heating Power | Kw | 72.4 | ||

| 总用电量 | Total Wattage | Kw | 146.4 | ||

|

其

他 |

机器重量 | Machine Weight | T | 21 | |

| 机器外形尺寸 | Machine Dimensions(L×W×H) | m | 7.0x2.5x4.0 | ||

Related Products

Recommend: Injection Molding Machine Vertical Injection Molding Machine Bakelite Injection Molding Machine BMC injection molding machine Insert injection molding machine